We offer a vast array of world class metal forming solutions beginning with pre-production services including product design, prototyping and complete tool & die design and build. Our Tool Room is extremely well equipped and houses the finest CNC, Vertical Machining and Wire EDM equipment available.

Product Design

The Ampex team is available for consultation as your project moves through the analysis, concept and synthesis stages of product design.

We have a great deal of experience working with ferrous and non ferrous metals, high strength low alloy steel, stainless steel and exotic alloys like beryllium copper.

Our engineering department will continue to provide all the additional expertise & support you need as your product matures through the design phase and into production.

Prototyping

Ampex has a long history of working with our Customers on proof of concept, prototyping and piloting of new products.

Our in-house capabilities allow us to develop prototypes to be tested for proper form, fit and function before moving into final production.

Looking to the future, we have been studying additive manufacturing and it's role in product development and prototyping. We are very excited about the way 3D Printing is redefining this landscape and expect to offer this level of rapid path of concept to market reality in the very near future.

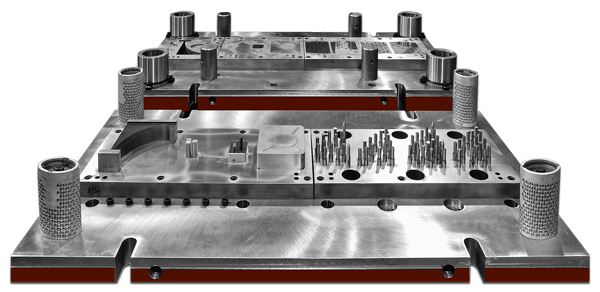

Tool and Die

Please Note and this is IMPORTANT: Unlike our competition, when Ampex builds you a tool, we guarantee and maintain it for the life of your part. You WILL NOT be asked for additional tooling dollars.

You will find our tooling costs to be highly competitive with China when built to OUR tool design. When comparing quality in an “apples to apples” scenario, Ampex is the clear winner in design, project management, build, completion time and cost.